TRANSPORT & HANDLING TESTING

General packaging

Performance testing of everyday packaging

Bottles |  Jerrycans |  Drums |  Boxes |

Sacks |  Film packaging |  Crates |  Consumer packaging |

Testing that achieves your benefits

| |

| Verification

| Validation

|

Simulate a distribution cycle

Test to ASTM D4169 or ISTA 2A/B. These are designed to simulate the shocks, loadings, and environments that your packaging may experience before it reaches the customer.

Improvement and risk mitigation

Test your packaging to your tailored requirements. This may depend on what you’re trying to achieve, the packaging specifications, how it’s transported, and how it’s used.| WE CONDUCT SHOCK AND IMPACT TESTING Shocks & impacts testingExcellent for simulating toppling loads, mishandling by forklifts, being thrown around during truck transport, crashing waves during sea transport, and rough handling by the consumer.

|

|

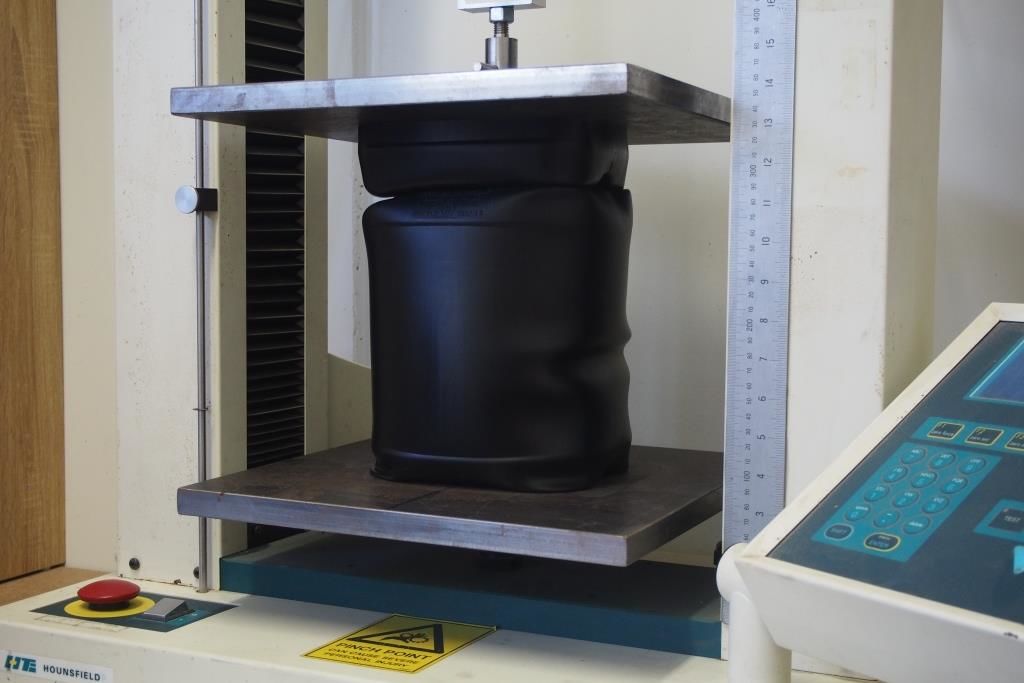

| WE CONDUCT COMPRESSION TESTING Compression resistance testingExcellent for simulating stacked pallets in warehouse storage along with the effects of creep and environmental degradation.

|

| WE CONDUCT TRANSPORT TESTING Transport simulation testingExcellent for simulating the repetitive shocking effect of multi-axis random/sinusoidal vibration experienced during transport.

Note: Ship (sea) vibration simulation is generally simulated due to its low-frequency and high-amplitude nature. Instead, sea transport is considered by testing a packaging’s resistance to shocks. These transport tests are performed with one of our associated laboratories. |

|

|

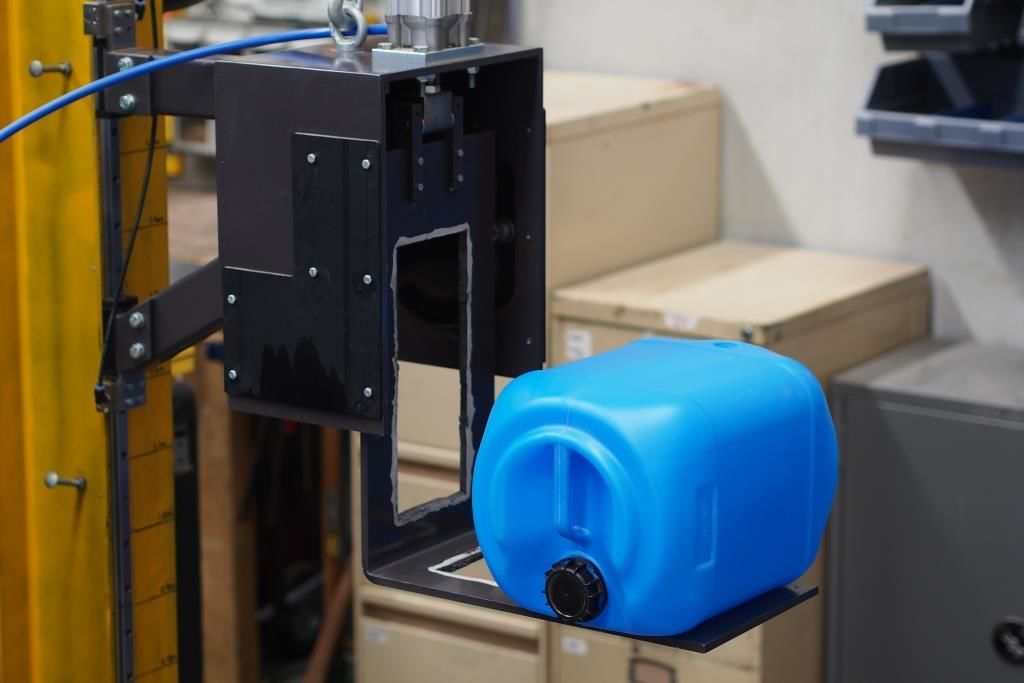

| WE CONDUCT PRESSURE TESTING Leakproofness and pressure resistance testingExcellent for determining seal integrity and simulating a packaging's resistance to excessive vapour pressure on hot days.

|

| WE CONDUCT COMPATABILITY TESTING Chemical resistance testingExcellent for ensuring that your packaging is compatible with it’s contents without distortion, stress-cracking, permeation, degradation or loss of strength.

|

|

|

| WE CAN SIMULATE HARSH ENVIRONMENTS Harsh environments testingExcellent for simulating the harshest environments that your packaging will endure during transport or in the elements.

Note: other environmental resistance (accelerated aging, weathering) tests include weather and UV resistance using QUV machines or Xenon machines. These tests are designed for materials testing. These weathering tests are performed with one of our associated laboratories. |

| WE CONDUCT WATER RESISTANCE TESTING Water resistance testingExcellent for ensuring moisture resistance if your packaging is left outside or placed in a high humidity environment.

|  |

Common packaging tests

|

|

Common test methods

- ASTM D7386 - Standard Practice For Performance Testing Of Packages For Single Parcel Delivery Systems

- ASTM D4169 - Performance Testing of Shipping Containers and Systems

- ASTM D6055 - Test Methods for Mechanical Handling of Unitized Loads and Large Shipping Cases and Crates

- ASTM D6179 - Test Methods for Rough Handling of Unitized Loads and Large Shipping Cases and Crates

- ISO 4180 (AS 2857) - Packaging — Complete, filled transport packages — General rules for the compilation of performance test schedules

- ISO 2206 - Packaging — Complete, filled transport packages — Identification of parts when testing

- ISO 10531 - Packaging — Complete, filled transport packages — Stability testing of unit loads

- ISO 8768 - Packaging — Complete, filled transport packages — Toppling test

- ISO 8474 - Packaging — Complete, filled transport packages — Water immersion test

- ISO 2876 - Packaging — Complete, filled transport packages — Rolling test

- ISO 2248 - Packaging — Complete, filled transport packages — Vertical impact test by dropping

- ISO 13355 - Packaging — Complete, filled transport packages and unit loads — Vertical random vibration test

- ISO 8318 - Packaging — Complete, filled transport packages and unit loads — Sinusoidal vibration tests using a variable frequency

- ISO 2875 - Packaging — Complete, filled transport packages and unit loads — Water-spray test

- ISO 2873 - Packaging — Complete, filled transport packages and unit loads — Low pressure test

- ISO 2247 - Packaging — Complete, filled transport packages and unit loads — Vibration tests at fixed low frequency

- ISO 2244 - Packaging — Complete, filled transport packages and unit loads — Horizontal impact tests

- ISO 2234 - Packaging — Complete, filled transport packages and unit loads — Stacking tests using a static load

- ISO 2233 - Packaging — Complete, filled transport packages and unit loads — Conditioning for testing

- ISO 12048 - Packaging — Complete, filled transport packages — Compression and stacking tests using a compression tester

- ISTA 2A: Packaged-Products weighing 150 lb (68 kg) or Less

- ISTA 2B: Packaged-Products weighing over 150 lb (68 kg)

- ISTA 2C: Furniture Packages

- ISTA 3A: Packaged-Products for Parcel Delivery System Shipments 70kg (150 lb) or Less (standard, small, flat or elongated)

- ISTA 3F: Packaged Products for Distribution Center to Retail Outlet Shipment 100 lb (45 kg)

- ISTA 6: FEDEX-A: FedEx Procedures for Testing Packaged Products Weighing Up to 150 lbs.

- ISTA 6: FEDEX-B: FedEx Procedures for Testing Packaged Products Weighing Over 150 lbs.