Load-deflection testing

Professionally measure your product's limits

| OUR UNIVERSAL TESTERS Broad range of loading capabilitiesOur universal testers have been designed to test a wide range of products and materials. We've achieved this with machine designs that can be adapted of suit your product, capacities for testing a wide range of materials, and they have automated functions.

|

|

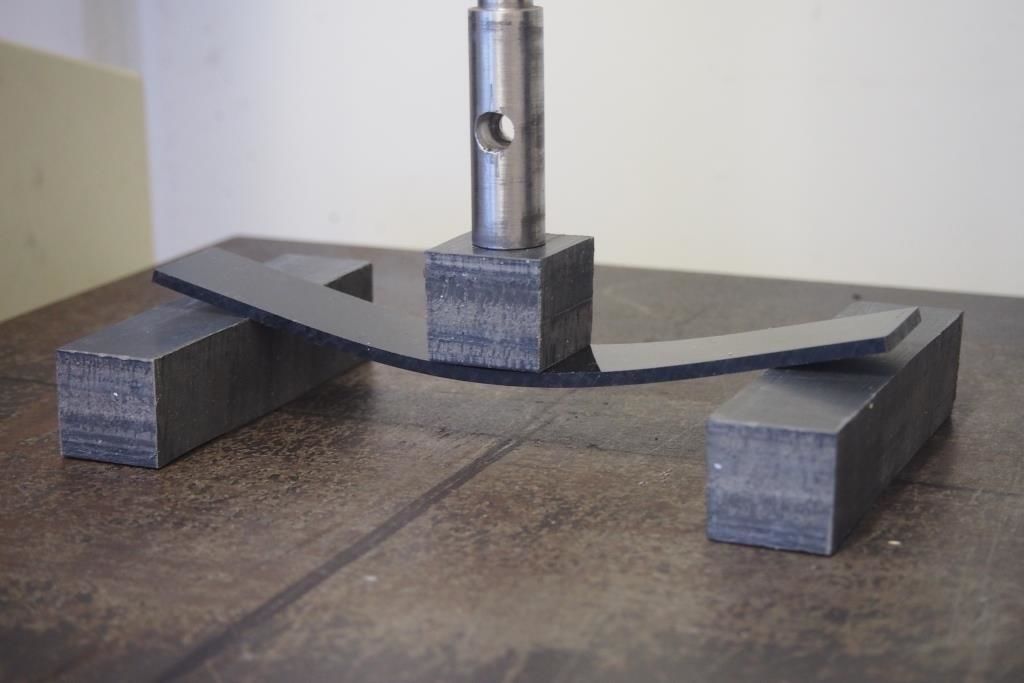

| WE CONDUCT SERVERAL TYPES OF LOADING TESTS Load your product in different configurationsOur load-displacement machines can be configured to test your product the way that you want.

|

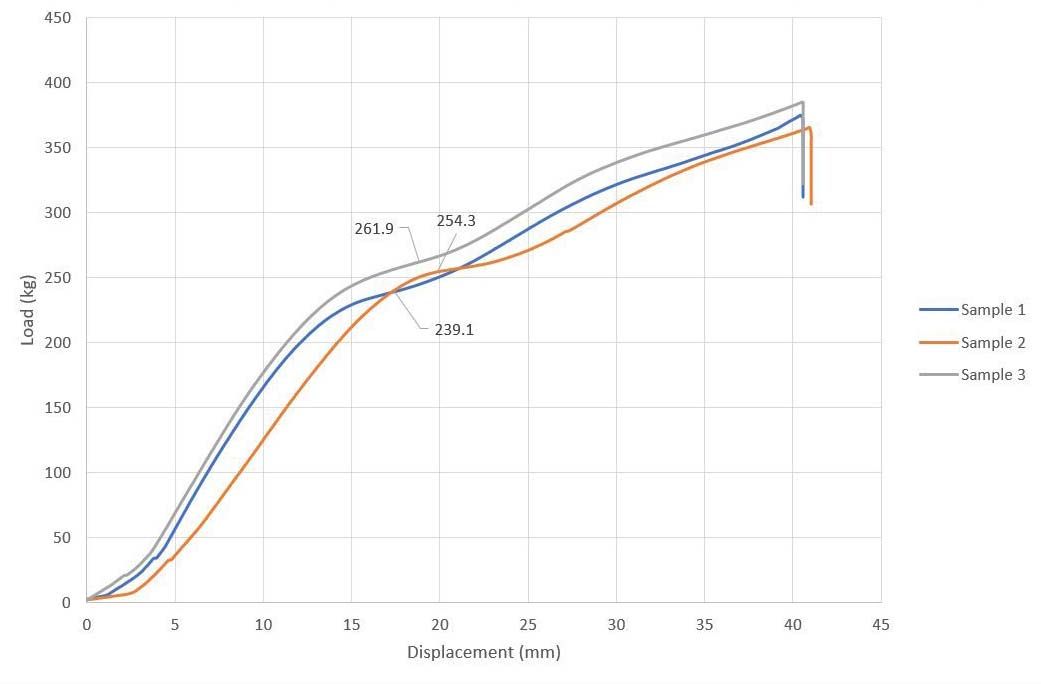

| WE ANALYSE TEST DATA Analyse your product’s behaviourUsing the load-displacement-time data collected from the test, we can manipulate the information to determine the below properties of your product.

|  |

| Other types of loading scenariosWhen we're not using a universal tester, we can still load your product the way that you'd like. This is generally achieved using steel dead weights as static loads, large pneumatic rams that can be regulated, or a crane. |

Common test methods

- ASTM D7030 - Test Method for Short Term Creep Performance of Corrugated Fibreboard Containers Under Constant Load Using a Compression Test Machine

- ASTM D642 - Determining Compressive Resistance of Shipping Containers, Components, and Unit Loads

- ISO 12048 - Packaging — Complete, filled transport packages — Compression and stacking tests using a compression tester

- ISO 2234 - Packaging — Complete, filled transport packages and unit loads — Stacking tests using a static load

- AS 1892.1 - Portable ladders Performance and geometric requirements

- AS 4291.1 - Mechanical properties of fasteners made of carbon steel and alloy steel Bolts, screws and studs

- AS 3996 - Access covers and grates

- AS/NZS 4442 - Office desks, office workstations and tables intended to be used as office desks - Mechanical, dimensional and general requirements and test methods

- AS/NZS 1891.4 - Industrial fall-arrest systems and devices Selection, use and maintenance

- AS 2741 - Shackles

- AS 2321 - Short-link chain for lifting purposes

- AS 4497 – Round slings - Synthetic fibre